Petroleum / Oil Interceptor Cleaning

Ensure Compliance and Prevent Environmental Fines

Our vacuum tanker services provide essential maintenance for your site’s oil/water interceptors, separators, and grease traps. These critical systems prevent harmful contaminants—such as petrol, diesel, oils, grease, and silt—from entering the public sewer system or local waterways.

What We Do:

Full Tank Emptying: We utilize our high-capacity vacuum tankers to safely and thoroughly remove all liquid, sludge, and accumulated sediment from the interceptor chamber.

High-Pressure Jetting: We clean internal walls, baffles, and pipework to ensure optimal flow and system performance.

Compliant Disposal: All waste (including contaminated water and hydrocarbons) is transported under the appropriate Waste Transfer Notes and disposed of at licensed treatment facilities, keeping your business fully compliant with environmental regulations.

Why It’s Essential:

Prevents Flooding: Regular cleaning prevents silt and sludge buildup that can block drains and cause costly site flooding.

Protects Infrastructure: Maintains the effectiveness of your drainage system and avoids expensive fines for pollution incidents.

Guarantees Function: Ensures your interceptor is working correctly to separate and retain hydrocarbons, protecting the environment.

Schedule your routine interceptor service today to guarantee compliance and protect your assets.

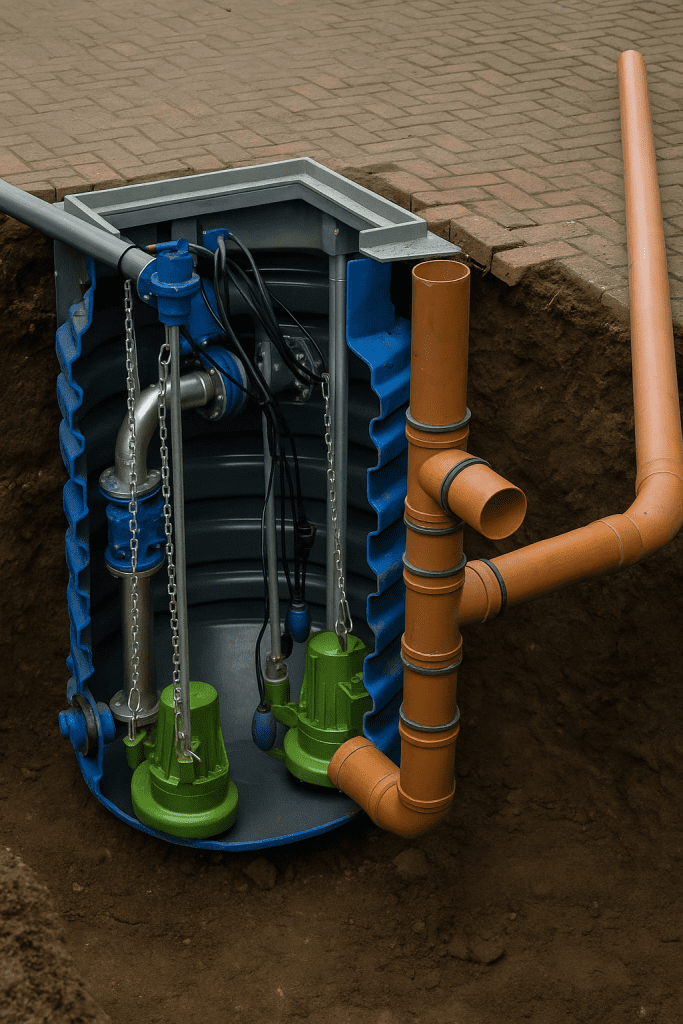

Pump Station Services & Emergency Repairs

Protect Your Property from Flooding and Costly System Failures

Pumping stations (or lift stations) are essential for properties where wastewater and surface water cannot drain by gravity alone. Failure is not an option for critical infrastructure like data centres. Our specialized service provides the necessary cleaning, maintenance, and rapid response to keep your pumps operating reliably.

Routine Maintenance (PPM)

We offer Pre-Planned Maintenance (PPM) contracts that include:

Tank Emptying & Cleaning: Using our vacuum tankers to thoroughly remove all accumulated sewage, effluent, silt, rags, and Fats, Oils, and Grease (FOG) from the wet well, preventing blockages.

Component Inspection: Visual and functional checking of crucial elements, including float switches, guide rails, control panels, and non-return valves.

Performance Testing: Running the pumps and alarms to confirm they activate correctly and discharge efficiently, ensuring system integrity.

Repairs & Emergency Response

A failed pump station can lead to catastrophic flooding and health hazards. We offer a 24/7 rapid response service:

Emergency Dewatering: Our vacuum tankers are deployed immediately to remove the overflowing liquid, mitigating flood damage.

Blockage Removal: Clearing severe blockages in the pipework or around the pumps that prevent normal operation.

Fault Diagnosis: Identifying and repairing common pump issues, including failed floats, electrical faults, and worn mechanical components.

Partner with us for reliable pump station maintenance and guaranteed peace of mind.

High-Pressure Drain Cleaning (Jet-Vac)

Clearing the Toughest Blockages with Power and Precision

Don’t let slow-running or blocked drains disrupt your business. We provide professional, comprehensive drain cleaning services for commercial properties using powerful High-Pressure Water Jetting combined with the efficiency of our Vacuum Tanker (Jet-Vac) units.

Our Advanced Drain Cleaning Process:

Blockage Removal: High-pressure water jets blast through the most severe obstructions, including hard scale, concrete, silt, fatbergs (FOG), and stubborn debris, restoring full flow quickly.

Debris Extraction: Unlike standard jetting that leaves debris downstream, our vacuum tanker immediately sucks up the dislodged material and wastewater, removing the blockage from the system entirely.

Root Cutting & Descaling: Specialized nozzles allow us to aggressively cut through intrusive tree roots and descale heavy mineral buildup inside the pipe walls.

Preventative Maintenance: We offer scheduled deep cleaning to remove the early stages of buildup, preventing future costly emergencies and protecting the integrity of your underground assets.

For a faster, cleaner, and more complete drain service, rely on our Jet-Vac technology.

How it Works

- Site Assessment – We review your glycol system and determine the safest, most efficient removal method.

- Vacuum Extraction – Using specialist equipment, we vacuum and contain all glycol waste.

- Legal Disposal – The waste is transported and processed in line with Environmental Agency regulations.

- Documentation Provided – You receive all necessary waste transfer documentation for your records and compliance.

Whether you’re decommissioning equipment, performing system maintenance, or managing glycol contamination, Glyco Environmental provides a trusted, compliant, and professional solution for bulk glycol removal.